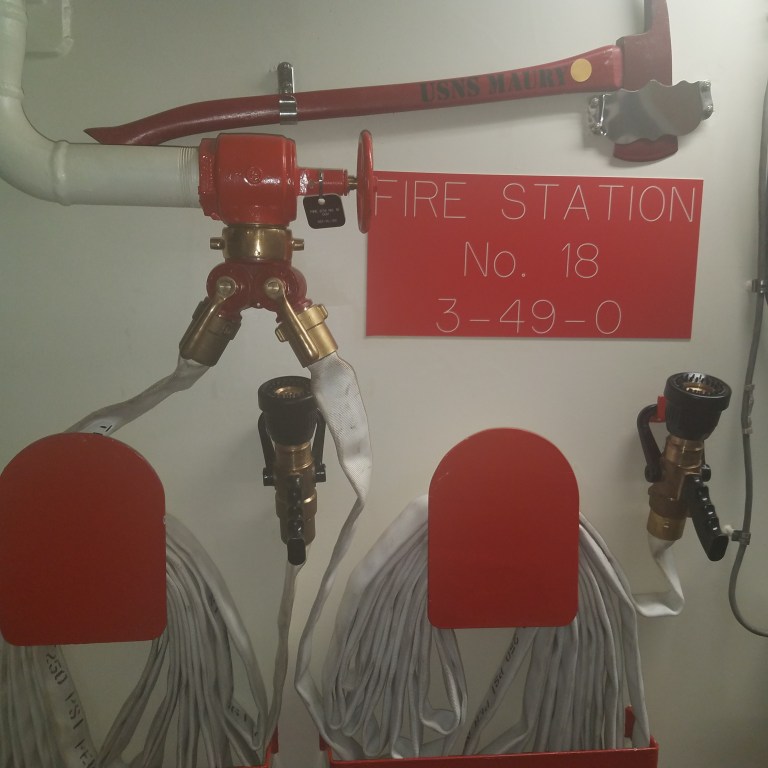

Well, here I am: a self-proclaimed expert of WD40, shining brass, unclogging valves, and coiling Fire Hoses. 😝 These Fire Stations take up so much of my time, and boy are they needy! They require a special kind of love and TLC. Haha, more like some PB Blaster, Pipe Wrenches, and the Wire Brushing kind of love! The fight against rust, both inside and outside the pipes, is a constant battle. There is nothing more corrosive than the salt and the sea, but the readiness of these Stations is a priority in my profession. When a fire happens on board a ship, there is no fire department to call. You’re all you’ve got out there, so the equipment has to work. There are several types of fires, but the Fire Main System is usually the main line of defense, and the method of choice. Inspecting and completing maintenance takes me about two full weeks of my time each month, but it’s worth it. As the Bosun and I like to say, “Butter and Beautiful, Baby!” 😁

Fire Stations are uniform throughout the industry, and are always painted red. They are comprised of a 2.5 inch Valve, a Wye Gate Valve, (2) 1.5inch 50ft Fire Hoses, and (2) Vari Nozzels. Hose lengths, and type of Nozzles can be swapped if needed. The other option is called an All Purpose Nozzle. A Vari Nozzle is shown in the picture above. Eductors can be added to fight the fire with Foam is needed, as well. To better understand how the Fire Main System works on a ship, it is very similar to the sprinkler system installed in public buildings. These piping systems are usually the red pipes that you see located in building stairways. This water system maintains a constant supply of water throughout the building and immediately supplies water to the sprinklers once a fire is detected. On ships the pipes are red and supply water throughout the ship. There are two pumps onboard that intake seawater when there is a fire.

Have you ever wondered what was on the inside of a Wye Gate? Me neither, but when its frozen shut, I guess you have to take it apart. 🤷♀️ That’s right, Officers in the Merchant Marine get quite dirty on the job! 😛 Never would have guessed that there would be a piece of wood inside, but when I took it apart, but hey, there it was. The wood expands as it soaks up water so it will create a better seal to help further block water flow when the Wye Gate is closed. I personally prefer the plastic ball valve design.

Of course we do get to have some fun! Each week we take out the Fire Hoses and test them up to 130-150psi. We test both Fire Pumps, and it is a chance to give a good flush of the whole system too. You would be surprised about how much gunk can build up in just one week. It’s also the time to see if there are any leaks, or if there are valves that are difficult to open.

Stay Salty!

– Emily