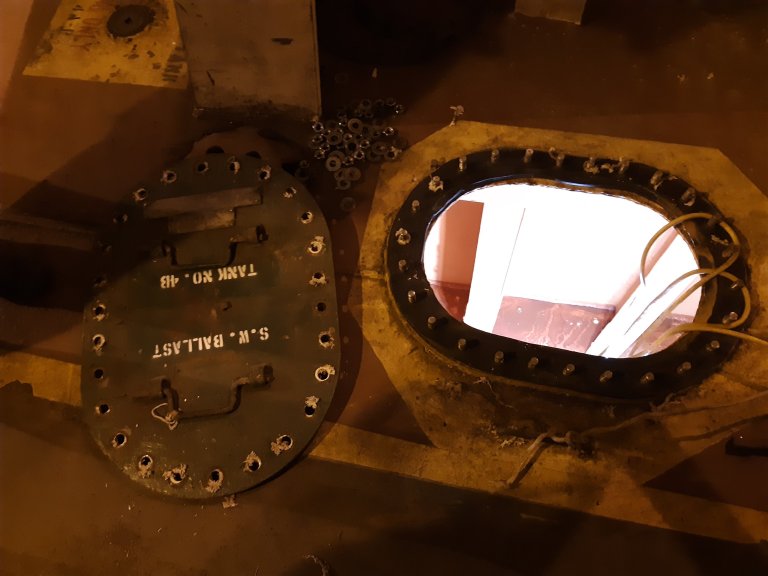

Tank Diving Day!! Ballasting and Deballasting a ship of this size can take DAYS, especially if you have to empty and inspect each tank one by one. Being an older ship design all pumping is done manually. There are no electronic systems to line up the valves and pumps, more importantly, nor is there a computer to monitor the changing tank levels. So it’s all hands on deck, with sounding tapes and chalk. Once a tank is emptied and the stability calculations are satisfied, the tanks can be opened and vented. Imagine manhole covers that go down into massive underhround water treatment plants, that’s kind if what this is like. One by one, with monitors, flashlights, and a team standing by above, you can make you way inside. Once you climb down the ladder, you can see the tanks. Dont forget a radio, your headlamp, and most importantly, if you see water, its deeper than you think and your socks might just get wet! 🤣 But once inside the tank as big as an entire room. That’s how big these tanks are! You always check the condition of the bulkheads and framing. What are we looking for mainly? Cracking and rust!! Salt is forever the enemy!! Being the bottom of the ship, the framing and double bottom is the only separation from the keel. Thus, a small crack or leak is a big problem! We also check the pumps and piping for potential blockages.

Not only is it great to see the tanks themselves, it helps to understand not only ship stability principles, but the ships framing design more fully. You can actually assess the framing: verticals, longitudinal, and double bottoms. It’s one thing to read these concepts in manuals, drawings, and text books, but once you see the designs: Ladage comes alive and much easier to grasp.

For those not familiar with ships, I’ll use a cheap motel as an example. It’s not the best example, but it works. Imagine a two story Motel with a basement. The basement is fortified with cement and cinder blocks. It houses the boilers, plumbing, electrical wiring, and is the foundation for the structure. The bottom of a ship is the same way. The bottom level of any ship has the piping, framing, and water ballast tanks. Tanks as big as rooms, like a basement. The difference is that they fill with water, (or fuel). The idea is to make the overall weight of the water heavier than the cargo above. This, and buoyant spaces, is what enables a ship to float. The layers on top involve the ships house, and cargo. Similarly, to the motel where the top floors are empty rooms with wood framing, walls, and guests. Cruise ships are essentially giant floating hotels, with a water ballast filled basement to ensure it floats. 👍

But its not all eduction, sometimes it’s just fun to get dirty! I couldn’t believe we did this operation within my first week aboard! Especially since these tanks hadn’t been opened in years!

Stay Salty!

-Emily